Official T-Shirt Wholesaler Blog

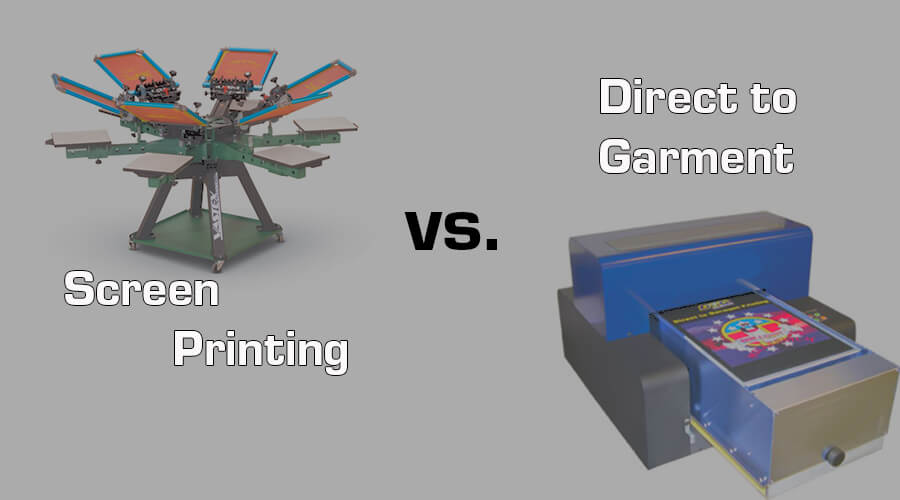

Screen printing and Direct-to-Garment (DTG) printing are both widely popular and each have their own advantages and disadvantages. In today’s spotlight series, we’ll hone in on different printing methods that work best in different situations to help our customers make the right choices for apparel orders large and small.

What is Screen Printing Used For?

Screen printing t-shirts and other apparel is more of a traditional process where the artwork or embellishment doesn’t need to be crystal clear. To accomplish a good screen printing, you’ll need to separate the artwork into different layers. These layers get turned into their own individual films so that they can in turn be burned into a screen for printing.

Once the screens are burned, an underbase is typically applied to make the details pop. After the underbase comes a flashing and curing stage before getting colored with details. Another round of flashing will usually be done before the apparel gets topped out.

The screen printing process still creates a good quality print that is also far faster to produce than DTG printing. This process is ideal for large orders.

What is DTG Printing?

DTG printing is printed straight from a computer onto the garment of choice. Garments set to be DTG’d will usually get pretreated before their colors are put on top. A dryer and heat press are then used to provide a good surface to print on.

The DTG machine will print a base with colors on top before getting another heat press. DTG printing produces a far better resolution; however, a major drawback is the process is not nearly as quick as screen printing. This process is ideal for smaller batch orders where print quality is paramount.

New comment

Comments